Scheelite Resources in a mine are abundant but not rich, and the average geological grade is only 0.41%. Affected by the dilution of mined ore and the dilution of tunneling by-products, the selected raw ore grade is about 0.30%. Compared with the same industry, it belongs to a low level. Since the establishment of the mine, the mine has been looking for ways to reduce the production cost, and discarding waste before separation is an effective way to reduce the production cost.

X-ray sensor waste disposal technology is a very mature application technology in the world. Foreign manufacturers of the equipment include redwave in Austria, Mogensen in Germany, Rados in Russia, tomra in Norway and other companies, and XRT intelligent mineral ore sorter manufactured by Ganzhou good friend Technology Co., Ltd. in China. The scheelite sorter uses this equipment to throw waste semi industrial test research on raw ore with particle size of 15 ~ 45 mm in the crushing section, in order to improve the raw ore dressing grade and reduce the production cost.

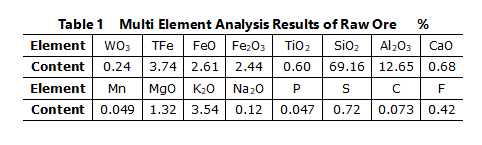

Scheelite in the mine is a single tungsten ore, which basically exists in the form of scheelite, with a distribution rate of 91.80% and a WO3 grade of 0.24%; The content of other valuable metals is low and has little comprehensive utilization value; Gangue is mainly composed of SiO2, followed by AI2O3, K2O and MgO. Scheelite is mainly embedded in the edge of late quartz vein and near the contact with early dark rocks. The particle size of mineral embedding belongs to medium coarse particle embedding, generally 0.1 ~ 3.0 mm. See Table 1 for multi-element analysis results of raw ore.

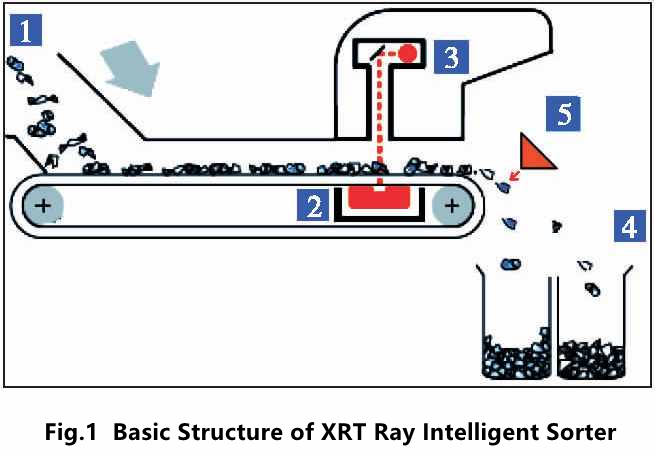

The theoretical basis of X-ray sorting is that the atomic energy level structure of each element is specific, and the energy of X-ray emitted during the transition after it is excited is also specific, so it is called characteristic X-ray. The existence of the corresponding element can be determined by measuring the energy of the characteristic X-ray, and the strength of the characteristic X-ray represents the content of the element. Using sensor and computer technology to identify solid materials one by one, and then using compressed air or mechanical devices as technical means to change the trajectory of materials to realize separation. The basic structure of XRT intelligent mineral ore sorter is shown in Figure 1.

(1) Identification accuracy. There are corresponding equipment products in the whole wavelength range of electromagnetic wave from AC wave to gamma ray, which makes it possible to select the best sensing technology or its best combination for ore properties and separation tasks to achieve accurate identification.

(2) Fast. About 40000 ores can be detected every second; The near infrared spectrum probe can measure 1 million spectra per second; It takes only a few milliseconds from the irradiation of the probe to the final decision on whether to change the trajectory of the ore block. It only takes a few milliseconds for the compressed air nozzle to eject the ore block once.

(3) Large capacity. The machine hour capacity of the existing equipment can meet the requirements of large-scale modern mining equipment. For the equipment with a maximum working width of 2.4 m, iron ore with ore feeding particle size of 12 ~ 40 mm can be selected, and the on-site operation has reached a processing capacity of about 700 t / h.

(4) Energy saving and environmental protection. One XRT intelligent mineral ore sorter with a processing capacity of 30 ~ 50 t / h consumes only 30 kW / h. In the case of power on and start-up, the specific small area in the XRT intelligent mineral ore sorter will produce X-ray radiation, while in the case of power failure, it will not produce X-ray radiation. For the X-ray source, labyrinth lead plate protection is adopted to isolate it from the outside world.

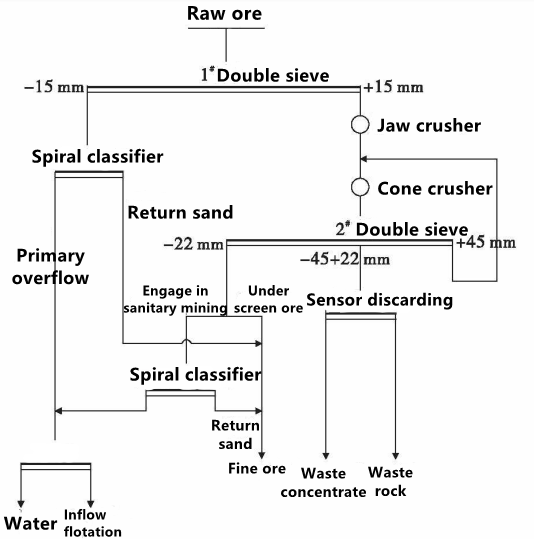

According to the service index of XRT intelligent mineral ore sorter, the waste raw ore is dumped, the intermediate particle size ore of 2# double screen in the crushing workshop of the concentrator is intercepted, and the open circuit process is used. The semi industrial test process of waste dumping is shown in Figure 2.

The semi industrial test site is equipped with equipment and facilities such as waste disposal equipment operation room, waste concentrate transportation belt, waste rock transportation belt and sampling platform. In operation, the two parameters of treatment capacity and waste rock grade are mainly adjusted to obtain better waste disposal effect. Each waste disposal test on site shall be controlled at about 4h, and one bag shall be sampled in 10min, each bag is about 25kg, and each sample is about 1% of the ore taken.

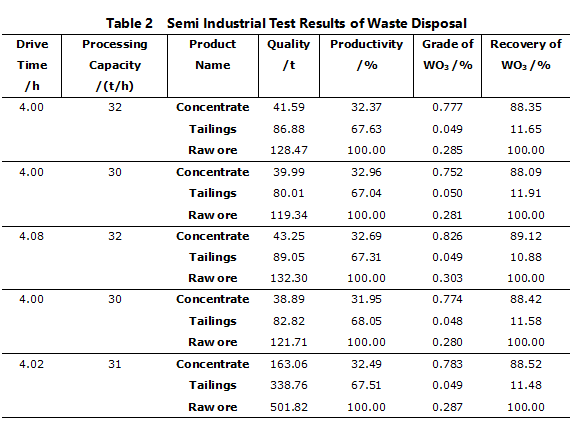

A total of 37 semi industrial tests for waste disposal were completed in 3 months, including 20 effective tests. The average waste rock WO3 in 20 tests was 0.054%. With the continuous improvement of test conditions, the results of the last few tests tend to be stable and reach the ideal index. The test results are shown in Table 2.

It can be seen from table 2 that the raw ore WO3 grade of several tests is similar and the waste throwing effect is similar; It is determined that when the grade of waste raw ore WO3 is 0.30%, the grade of waste rock WO3 is about 0.05%, the grade of concentrate WO3 is about 0.80%, the waste rate can reach 68%, and the concentrate recovery can reach more than 88%.

(1) XRT intelligent mineral ore sorter can effectively separate scheelite raw ore, improve raw ore dressing grade and reduce production cost; The equipment has the advantages of high degree of automation, simple operation and small floor area.

(2) The semi industrial test results of XRT intelligent mineral ore sorter in a scheelite concentrator in Hunan show that when the feed WO3 grade is about 0.30%, the grade of waste rock WO3 is less than 0.05%, the grade of concentrate WO3 is about 0.80%, the rejection rate can reach 68%, and the concentrate recovery rate can reach more than 88%.

(3) On the premise of keeping the grinding and flotation capacity of the existing concentrator unchanged at 1500 t / d, a scheelite concentrator in Hunan can realize the capacity expansion transformation only by carrying out the docking transformation of waste disposal corresponding technologies in the crushing section. The raw ore processing capacity can be increased to 2300 t / d, the annual output of tungsten concentrate can be increased to about 2200 t, and the average unit raw ore production cost can be reduced by 32.74 yuan / t compared with that before the technical transformation.

sales@hot-mining.com