Product Introduction:

HCC Intelligence Coarse Coal Centrifuge is mainly used to separate suspended solid particles and liquids. It is widely used in coal processing, mineral processing, water treatment and other industries. Based on the IoT, sensors, and big data platform, HCC coarse coal centrifuge can be more intelligent--online fault monitoring and predictive maintenance.

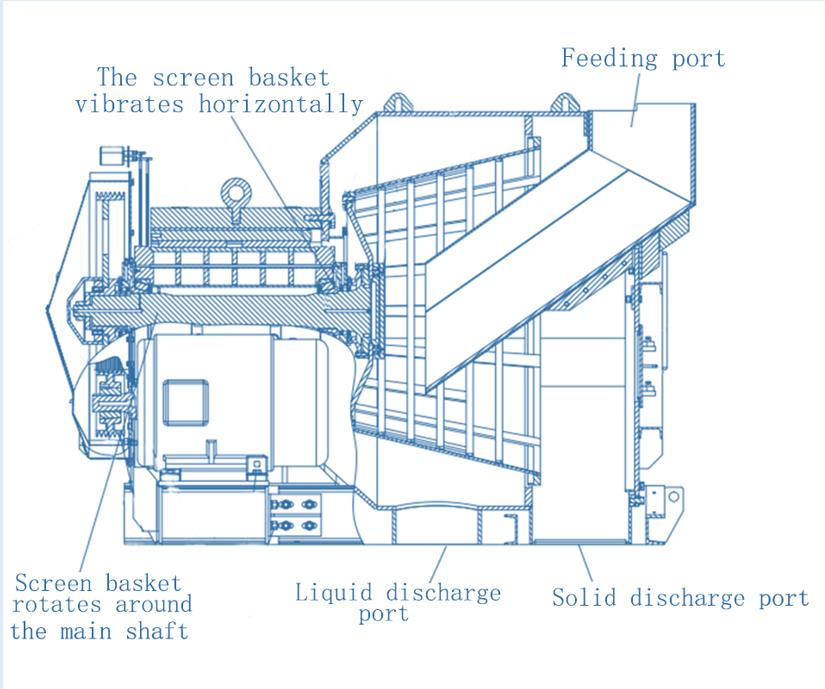

Working Princple:

The centrifuge is equipped with a slightly tapered screen basket, which opens at one end of the larger diameter of the cone. The screen basket rotates around its horizontal axis and vibrates rapidly along the direction of the horizontal axis at the same time.The mineral was feed through the top of the machine and falls into the screen basket. and mineral feed is pressed to the basket by centrifugal force.During this process, the surface water is removed from the mineral and forced through the apertures of the basket. At the same time, the mineral is conveyed along the inner side of the basket by vibration. Finally, the dewater mineral was discharged out of the screen.

Product features:

1. High working efficiency, low product moistures, low coal loss rate.

2. Wide particle size range and strong processing capacity

3. Low energy consumption; reduce the production costs of coal preparation plant.

4. Less easy wear parts, lower raw coal crushing rate.

5. The structure is simple, flexible, durable and easy to maintain.

6. Reduce plant height and the investment cost

7. Vibration balance and low noise.

8. Optimum design for the actual demand of coal industry

Technical advantage:

1. All the key components of the equipment are selected from international well-known brands with excellent equipment performance and long service life.

2. The exciting source of the equipment adopts two independent vibration motors, which has great excitation force and good vibration effect.

3. The amplitude of vibration motor is 2 to 6mm, which can adjust the amplitude conveniently.

4. The impact force of the spindle and bearing is small, and the vibration of the screen basket is uniform.

5. The use of polyurethane bumper block and damping rubber mounts reduces noise and foundation vibration

6. The integrated design of feed chute and centrifuge door plate made the material also vibrates when through the chute, ensuring the uniformity and looseness of feeding material.

7. The rotary machine adopted the pressurized lubrication system with thin oil. The system has three functions: lubrication, cooling and lubricating oil purification.

8. All the consumable parts are protected by polyurethane or high alumina ceramic lining, which prolongs the service life of the equipment.

9. The hinge door plate and the screen basket disassembly tool for special use facilitate the replacement of the screen basket.

10. Realize intelligent control of mechanical & electrical integration of equipment, on-line monitoring of bearing temperature, early warning, improving the reliability of equipment operation.

11. Motor position and opening direction can be flexibly selected with users.

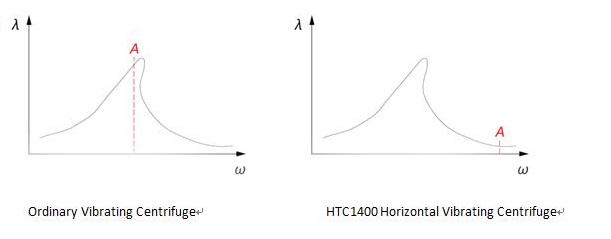

Vibration curve:

The HCC series horizontal vibration centrifuge adopts a far resonance linear vibration system, with stable vibration and high frequency. The following is the comparison of the vibration system characteristic curves between the ordinary centrifuge and HCC centrifuge. It can be seen that the working point (point A) of HCC centrifuge is a very smooth, approximate straight line, and its working frequency is much higher than the natural frequency, which shows that it has strong adaptability to the field, and it is not sensitive to the change of materials feeding, and its amplitude is stable.

Technical data:

No | Type | Feed granularity range (mm) | Processing capacity (t/h) | Product moistures (%) | Slime water loss rate(%) | Ordinary life of screen basket (month) | Motor power (kw) | Total power of equipment (kw) | Outline dimension (mm) | Total weight (kg) | ||

Drive motor | Vibration motor | Oil pump motor | ||||||||||

1 | HCC1100 | 0.5~50 | 140~180 | 5~9 | 2.5~3.5 | 3~6 | 37 | 2×3.0 | 0.75 | 43.75 | 2586×2743×1877 | 7275 |

2 | HCC1300 | 0.5~50 | 180~210 | 5~9 | 2.5~3.5 | 3~6 | 45 | 2×3.0 | 0.75 | 51.75 | 2586×2743×1877 | 7324 |

3 | HCC1400 | 0.5~50 | 210~250 | 5~9 | 2.5~3.5 | 3~6 | 45 | 2×4.0 | 0.75 | 53.75 | 2959×2759×1917 | 8229 |

4 | HCC1500 | 0.5~50 | 300~350 | 5~9 | 2.5~3.5 | 3~6 | 75 | 2×8.4 | 0.75 | 92.55 | 3257×3125×2192 | 11430 |

5 | HCC1650 | 0.5~50 | 370~410 | 5~9 | 2.5~3.5 | 3~6 | 75 | 2×8.4 | 0.75 | 92.55 | 3314×3136×2211 | 12500 |

On-site Application:

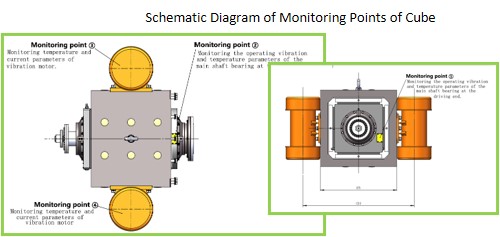

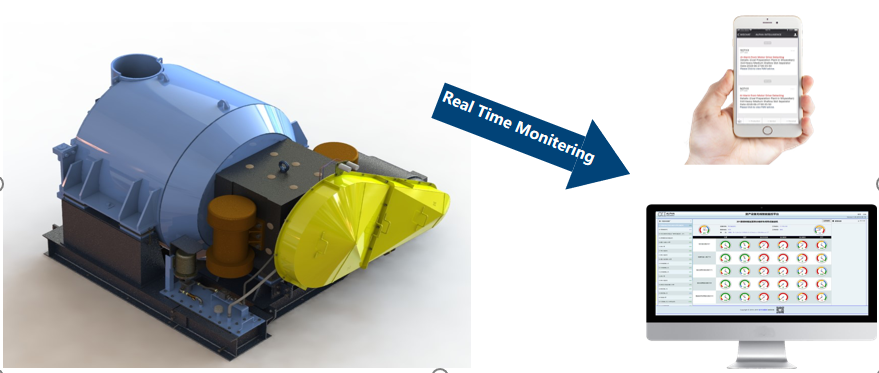

Intelligent Function:

In order to ensure the long-term performance of the centrifuge, we can specially customize the built-in wireless sensor for centrifuge, which can real-time monitor the operation status of the core components of the centrifuge.

Real-time monitoring of solid particle content in centrifugal fluid, through analysis, real-time understanding of the screen basket wear situation. Convenient and timely replacement of vulnerable parts, reduce abnormal shutdown in production. The early warning information is pushed in real time, and the production personnel can understand the information and process it in the first time.